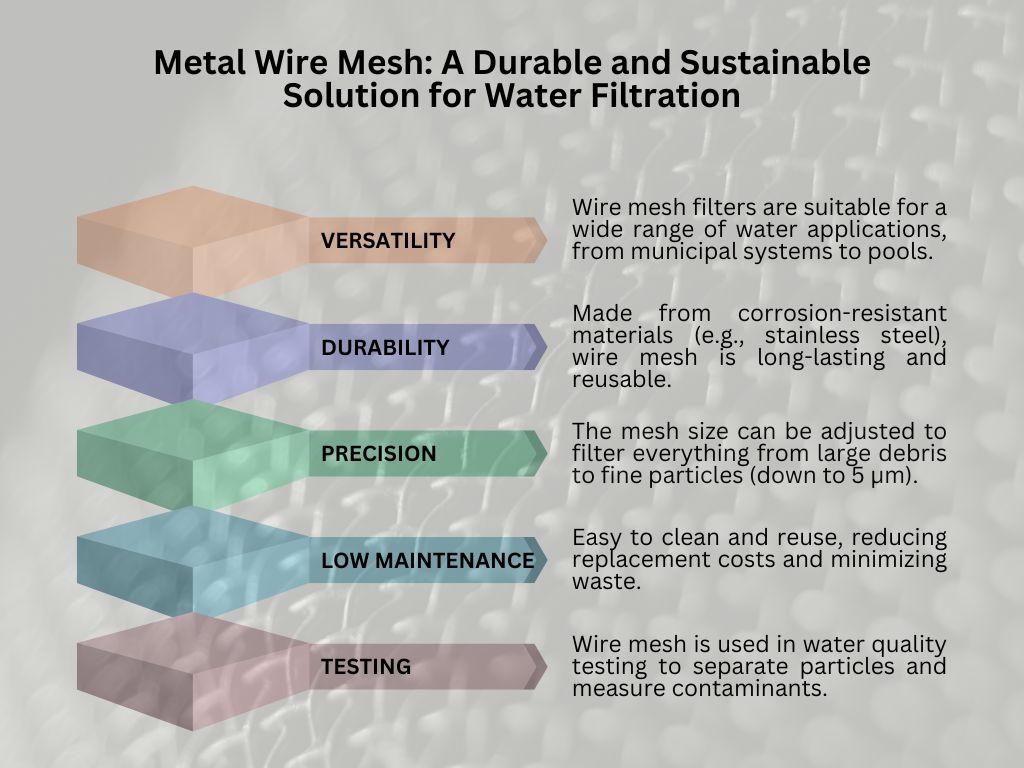

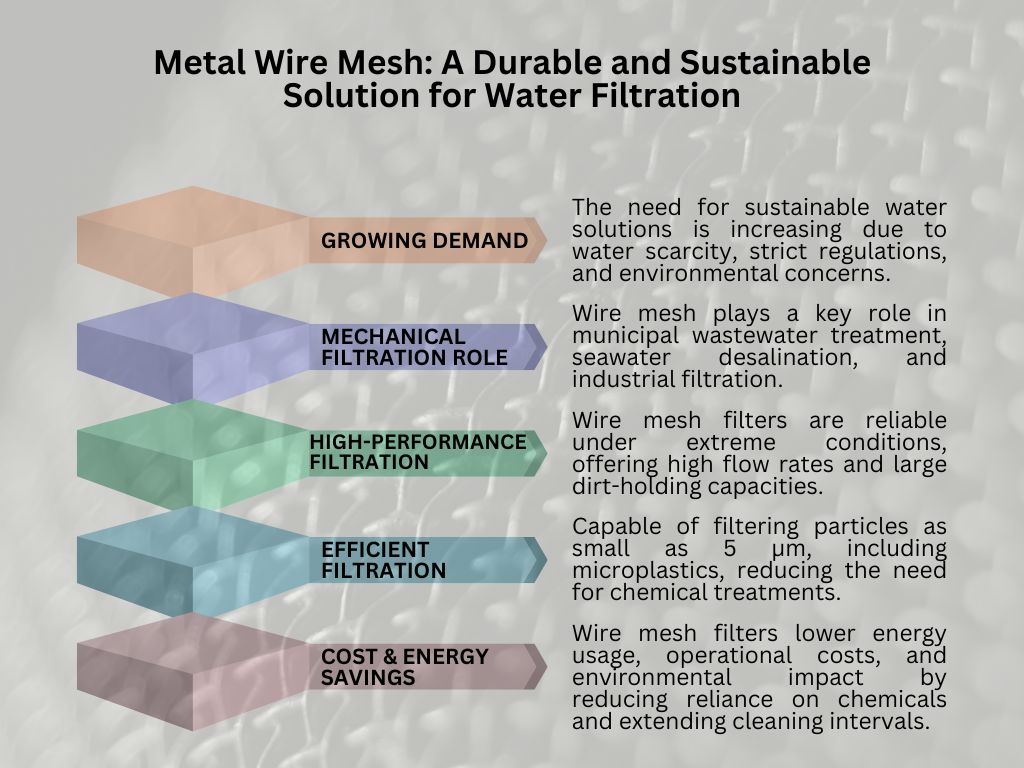

The growing global demand for clean water has made water filtration and testing more essential than ever. Whether for large-scale industrial operations or home water purification systems, maintaining water quality and safety is a top priority. Among the various technologies used for water treatment, wire mesh has emerged as a crucial component. It provides effective, durable, and precise filtration solutions, playing a key role in tackling water contamination and ensuring clean water.

Why Wire Mesh Is Essential in Water Filtration Systems

Wire mesh has become a vital part of water filtration systems. Its versatility allows it to be used in various filtration processes, from removing large particles to fine contaminants. Wire mesh can filter down to as small as 5 microns, efficiently trapping microplastics, bacteria, and other harmful substances often found in water.

Wire mesh is integral to many water filtration systems, including those in desalination plants, wastewater treatment facilities, and residential filters. With increasing concerns about pollutants like microplastics, the ability to filter out these tiny particles has become a critical objective. Wire mesh helps address these concerns by providing a reliable means of purifying water, making it safer for consumption and improving the quality of water in the environment.

Key Benefits of Wire Mesh in Water Filtration and Testing

Durability and Consistency

A key benefit of using wire mesh in water filtration is its capacity to deliver reliable and consistent performance over time. Unlike other filter materials that may have fluctuating pore sizes, wire mesh offers a uniform structure. This consistency ensures reliable filtration results, which is crucial when accuracy is required for water testing.

Reusability

Wire mesh filters function as surface filters, they can be cleaned and reused. This is especially important in industries where continuous filtration is necessary. Unlike disposable filters, which must be replaced regularly, wire mesh filters can be backwashed and reused, making them a more economical and environmentally friendly option.

Cost-Effectiveness

The ability to clean and reuse wire mesh filters helps reduce long-term operational costs. By eliminating the need for frequent filter replacements, businesses and households save money on replacements and maintenance. This cost efficiency is one reason wire mesh is widely adopted in both residential and industrial filtration systems.

Wire Mesh in Challenging Environments

Wire mesh is highly effective in harsh environments, particularly in systems exposed to extreme conditions. For example, in seawater desalination processes, wire mesh filters are made from corrosion-resistant materials like stainless steel. These materials are essential for ensuring that the filters can withstand the corrosive effects of saltwater while maintaining their filtration capabilities.

In desalination plants, reverse osmosis (RO) systems need high-quality pre-filters to protect the delicate membranes from damage caused by debris and large particles. Wire mesh filters serve this role by capturing larger particles before water passes through the RO system, ensuring the process runs efficiently and the final product is safe for consumption.

Applications of Wire Mesh in Water Filtration

Wire mesh is used in a variety of water filtration applications, depending on the size of particles to be filtered and the type of filtration system.

Below are several common applications:

Industrial Water Filtration

In large-scale industrial applications, wire mesh is often used as a pre-filter for reverse osmosis systems. By filtering out larger particles before the water reaches the RO system, wire mesh helps prevent blockages and extends the life of the membranes, improving the overall efficiency of the system.

Residential Water Filtration

Wire mesh is also used in household water filtration systems, ensuring that water used in appliances like dishwashers and washing machines is free from impurities. This helps maintain the quality of water entering the home and reduces wear and tear on household appliances.

Wastewater Treatment

Wire mesh is widely employed in wastewater treatment plants, where it is used in drum filters and filter panels. It efficiently removes debris and contaminants from wastewater before further treatment or disposal, improving the efficiency of the system and reducing maintenance needs.

Industries That Depend on Wire Mesh

Wire mesh is not only crucial in water filtration but also plays an important role in several other industries that rely on precision filtration and separation.

These industries include:

Pharmaceutical Industry

In the pharmaceutical sector, wire mesh screens are used in filtration processes to maintain exceptionally high levels of purity. These screens remove impurities from liquids and gases used in the production of medications and vaccines, ensuring that the final products meet strict quality and safety standards.

Petrochemical Industry

The petrochemical industry depends significantly on wire mesh for filtration. It is used to separate gases and liquids at various stages of the refining process. Wire mesh helps ensure that the final petrochemical products are free from impurities, maintaining the quality and safety of these materials.

Water Treatment

In water treatment plants, wire mesh plays a crucial role in ensuring the delivery of clean drinking water. The screens filter out various contaminants and particles from raw water before it is treated further or distributed to households. This makes wire mesh an essential component in ensuring the safety and quality of water supplied to communities.

The Role of Research and Development in Water Filtration Innovation

Continuous research and development (R&D) are essential to improving water filtration technologies. By integrating feedback and keeping up with technological advancements, it can be ensured that products stay at the forefront of water testing and filtration solutions.

This helps in developing filtration systems that are tailored to specific industry needs, improving performance and efficiency in a variety of applications. Focus on innovation ensures that water filtration systems will continue to evolve, meeting the challenges of providing clean water in the future.

Sustainability in Water Filtration Systems

Wire mesh filtration offers significant environmental benefits. Unlike disposable filters that need to be replaced regularly, wire mesh can be cleaned and reused multiple times. This reusability helps reduce waste and supports more sustainable filtration practices. By reducing the need for single-use filters, wire mesh contributes to a more eco-friendly approach to water treatment.

With growing awareness of environmental issues, companies are focusing on providing sustainable water filtration solutions. This not only helps to preserve resources but also ensures that communities can continue to rely on clean water sources for years to come.

Wire mesh has become an essential component in modern water filtration and testing systems. Its durability, precision, and reusability make it a versatile and reliable solution for both industrial and residential water filtration needs. From desalination plants to household water filters, wire mesh provides an effective means of ensuring safe, clean water.

With a commitment to innovation and sustainability, wire mesh is poised to play a key role in addressing the future challenges of water treatment. As industries and communities continue to face the growing demand for clean water, wire mesh remains an indispensable tool in delivering safe, high-quality water for all.

Leave a Reply