Borewells are a critical water source for communities, especially in areas where surface water may be scarce or contaminated. However, borewell water can become polluted due to various factors such as industrial waste, agricultural runoff, or wastewater leakage. Consistent water testing is crucial to guarantee the maintenance of water quality. This guide explores the importance of water testing, particularly focusing on parameters like Chemical Oxygen Demand (COD), Biochemical Oxygen Demand (BOD), and Oil & Grease, by evaluating both the inlet and outlet water from borewells.

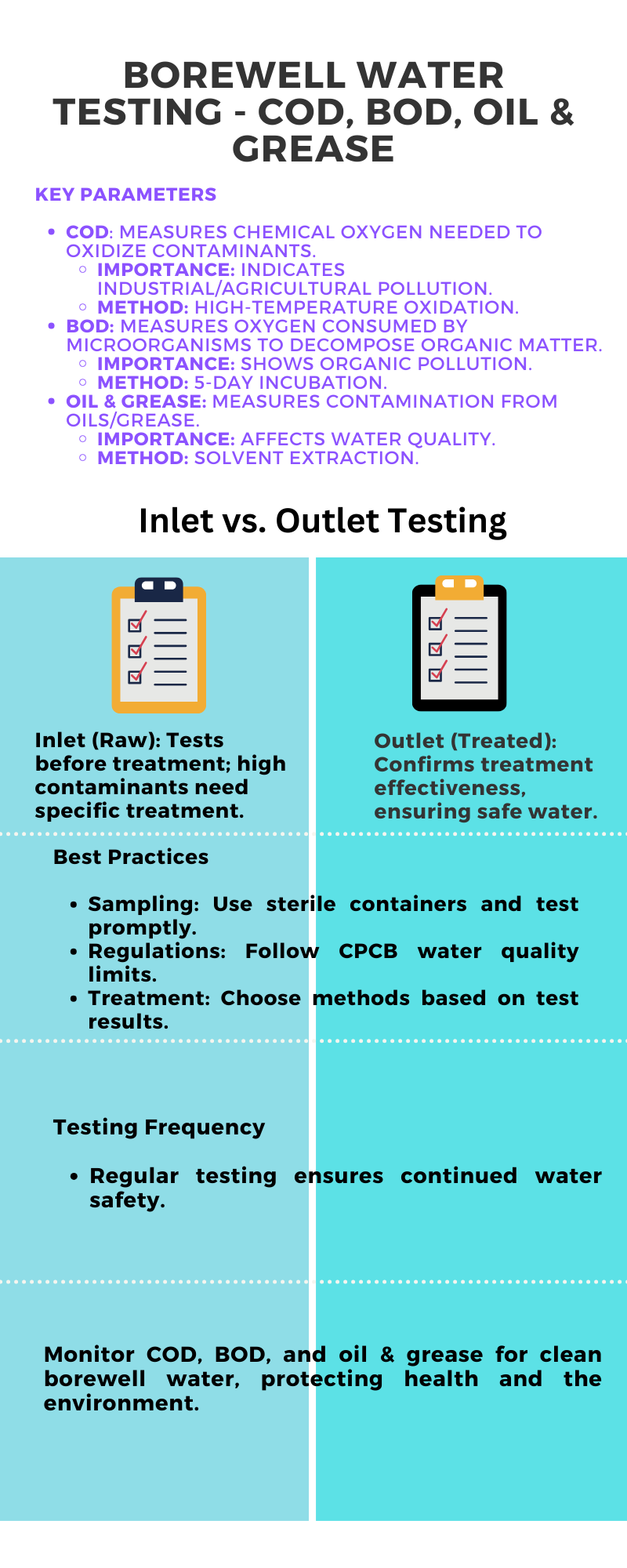

Key Water Quality Parameters in Water Testing

Chemical Oxygen Demand (COD) COD measures the amount of oxygen needed to chemically oxidize both organic and inorganic substances in water. It provides insight into the level of contamination, especially from pollutants such as industrial effluents or toxic chemicals. High COD levels in borewell water may indicate contamination from agricultural or industrial sources, signaling the need for treatment.

Water Testing Method: To measure COD, a strong oxidizer like potassium dichromate is added to a water sample, which is then heated at high temperatures. The quantity of oxygen used in this procedure is measured, and the final result is given in milligrams per liter.

Importance: Elevated COD levels point to significant pollution, often from industrial or agricultural discharges, which could make the water unsuitable for consumption or other uses without proper treatment.

Biochemical Oxygen Demand (BOD) BOD quantifies the amount of oxygen microorganisms consume to decompose organic matter in water over five days at 20°C. It reflects the biodegradability of organic pollutants, serving as an indicator of water quality.

Water Testing Method: The BOD test involves incubating a water sample for five days at 20°C and measuring the change in dissolved oxygen levels before and after incubation. The result is reported in milligrams per liter.

Importance: High BOD values suggest the presence of organic pollutants, which can deplete oxygen levels in water, harming aquatic ecosystems and diminishing water quality.

Oil & Grease Oil and grease in water typically signal contamination from industrial waste, motor oil, or sewage. These contaminants form surface layers that can degrade water quality and damage equipment like irrigation systems or machinery.

Water Testing Method: The common method for testing oil and grease involves extracting the substances with a solvent and then measuring their concentration by assessing the weight or volume of the extracted material.

Importance: Excessive oil and grease levels indicate contamination from industrial activities or improper waste disposal, which can significantly impair water quality and harm surrounding environments.

Inlet and Outlet Water Testing: Evaluating Treatment Effectiveness

Water testing at both the inlet (raw water) and outlet (treated water) stages is crucial to ensure that treatment processes are functioning as intended. This dual testing approach helps verify that contaminants like COD, BOD, and oil & grease are effectively reduced, ensuring that the treated water meets safety standards for its intended use.

Inlet Water Testing:

Inlet water refers to raw water extracted directly from the borewell before any filtration or treatment. Testing this water is essential to assess the levels of COD, BOD, and oil & grease, which will guide the treatment process design.

Inlet Water Contamination:

High COD, BOD, or oil & grease levels in the inlet water will require specific treatment methods, such as coagulation, biological treatment, or advanced filtration, to meet water quality standards.

Outlet Water Testing:

Outlet water refers to the treated water that is prepared and suitable for use. Testing at this stage ensures the treatment processes have effectively reduced contaminants, with COD, BOD, and oil & grease levels meeting permissible limits set by regulatory bodies.

Quality Assurance:

To ensure that the treated water is safe for consumption, agriculture, or industrial use, outlet water testing ensures compliance with established water quality standards, protecting human health and the environment.

Key Considerations for Effective Water Testing

Proper Sampling and Preservation:

Accurate water testing depends on correct sampling techniques. Samples should be collected in sterile containers, stored under appropriate conditions, and analyzed promptly to prevent contamination or changes in the sample.

Adhering to Regulatory Standards:

Water quality standards set by regulatory authorities, such as the Central Pollution Control Board (CPCB), must be followed. These standards outline the permissible limits for parameters like COD, BOD, and oil & grease to protect public health and the environment.

Treatment Approaches:

Based on the results of COD, BOD, and oil & grease tests, different treatment methods might be necessary. These may include physical treatments like filtration, chemical methods such as coagulation, or biological treatments like activated sludge systems.

Frequency of Water Testing:

Routine water testing is necessary to ensure ongoing water quality and to monitor the effectiveness of the treatment system. The frequency of testing should be based on water usage and the level of contamination.

Conclusion

Regular water testing of borewell water, focusing on key parameters such as COD, BOD, and oil & grease, is crucial for maintaining high water quality standards. By conducting thorough inlet and outlet water testing, stakeholders can monitor the effectiveness of water treatment systems and ensure that water is safe for various uses, including consumption, agriculture, and industrial applications. With appropriate testing and treatment methods, borewell water can remain a reliable resource while protecting both public health and the environment.

Leave a Reply