As the world rapidly evolves, diesel continues to be a cornerstone of industrial and commercial operations across the globe. In India, diesel plays a crucial role in powering a wide variety of equipment, including generators, agricultural machinery, construction vehicles, and transport fleets. Its applications extend to backup power solutions for critical facilities such as hospitals, educational institutions, and large corporations. With such heavy reliance on diesel, it becomes vital to ensure its quality and performance through systematic testing. This is where diesel testing laboratories become indispensable.

Why Diesel Testing is Crucial for India’s Industrial Landscape

In India, the wide usage of diesel across sectors highlights the importance of ensuring its quality through rigorous testing. Diesel testing is essential for ensuring the efficient functioning of diesel engines, minimizing downtime, and preventing costly repairs. The need for fuel quality control also stems from the growing focus on environmental regulations. By ensuring that the fuel meets specified standards, industries can avoid potential operational challenges, environmental harm, and regulatory violations.

Key Reasons for Diesel Testing in India:

Preventing Engine Failures: Diesel engines rely on the quality of fuel for optimal performance. If the fuel is contaminated with impurities, such as water, dirt, or excess sulfur, it can cause engine malfunctions, leading to frequent breakdowns and costly repairs. Regular testing helps identify such issues before they lead to expensive failures.

Improving Fuel Efficiency: The efficiency of a diesel engine depends on the fuel’s purity. Contaminants in the fuel can cause poor combustion, which reduces engine efficiency and increases fuel consumption. Testing diesel ensures that it meets quality standards, optimizing fuel use and reducing operational costs.

Adhering to Environmental Standards: As the world becomes increasingly concerned about air pollution, countries like India are implementing stricter regulations regarding emissions from diesel engines. High levels of sulfur and other pollutants in diesel contribute significantly to air pollution. Testing the fuel for sulfur content ensures compliance with environmental standards, thereby reducing harmful emissions and supporting sustainability efforts.

Reducing Operational Costs: Using high-quality diesel not only helps avoid engine damage but also reduces maintenance costs. Poor-quality fuel can lead to the accumulation of deposits in engines, reducing their lifespan. Regular fuel testing ensures that diesel is free from harmful substances, promoting smoother engine operations and minimizing the need for repairs and replacements.

Types of Diesel: Understanding LDO and HFO

Diesel fuel is not a one-size-fits-all solution. The two most common types of diesel used in various industries are Light Diesel Oil (LDO) and Heavy Fuel Oil (HFO). These fuels have distinct characteristics and require different testing methods to ensure they meet industry standards.

- Light Diesel Oil (LDO)

LDO is a refined and lighter grade of diesel fuel primarily used in vehicles, furnaces, and boilers. It is designed for engines that require efficient combustion for better performance. LDO is also used in backup generators and smaller-scale industrial applications. However, to ensure optimal performance, it is crucial to test LDO for contaminants such as sulfur, water, and sediment.

- Heavy Fuel Oil (HFO)

HFO is a denser, heavier grade of diesel fuel primarily used in large-scale industrial applications, including marine vessels and power plants. It is produced from the residuals of crude oil refining and has a higher sulfur content compared to LDO. Due to its composition, HFO requires more detailed testing to ensure it does not cause damage to machinery and meets emission standards.

Key Aspects of Diesel Testing: LDO and HFO

When it comes to testing diesel fuels like LDO and HFO, it is crucial to evaluate several key parameters to ensure the fuel’s quality and performance:

Sulfur Content: One of the primary concerns in diesel testing is the sulfur content in the fuel. Sulfur is a major contributor to air pollution, and its emission during combustion can lead to the formation of harmful gases like sulfur dioxide. With stricter environmental regulations in place, it is important to measure sulfur levels in both LDO and HFO to ensure compliance with permissible limits.

Calorific Value: The calorific value measures the amount of energy that can be obtained from the fuel during combustion. A higher calorific value means more energy can be produced from a smaller quantity of fuel, improving fuel efficiency. Testing the calorific value is essential for determining how effective the fuel will be in powering engines and industrial systems.

Purity and Contamination: Diesel fuel needs to be free from contaminants such as water, dirt, or microbial growth. Even small amounts of water or particulate matter can cause serious damage to fuel systems, leading to clogging, corrosion, and engine inefficiency. Diesel testing ensures that the fuel is clean and free from harmful impurities.

Viscosity and Density: The viscosity and density of diesel fuel are important factors that affect its flow and combustion properties. For HFO, these properties must be carefully monitored to prevent issues such as clogging in fuel lines and inefficient burning in engines. Proper viscosity ensures that the fuel can be pumped and combusted effectively, contributing to better engine performance.

Compliance with Industry Standards: Diesel fuel must meet certain industry standards set by organizations such as the American Society for Testing and Materials (ASTM) and Original Equipment Manufacturers (OEMs). These standards ensure that the fuel meets specific quality and performance criteria, making it suitable for use in various industrial applications.

Role of Diesel Testing Labs in India

Diesel testing laboratories, like Anacon Laboratories, play an essential role in ensuring that diesel fuels meet the required quality standards. These labs use advanced analytical equipment to assess various parameters of diesel fuel, ensuring that it is free from impurities and compliant with regulatory requirements. With a focus on accurate and reliable testing, these labs provide businesses with the insights needed to make informed decisions about fuel use and maintenance.

Anacon Laboratories offers comprehensive diesel testing services, including the analysis of sulfur content, calorific value, water and sediment content, and adherence to ASTM and OEM standards. The laboratory ensures that both LDO and HFO fuels meet the required specifications, helping industries optimize performance and comply with environmental regulations.

The Growing Need for Diesel Testing in India

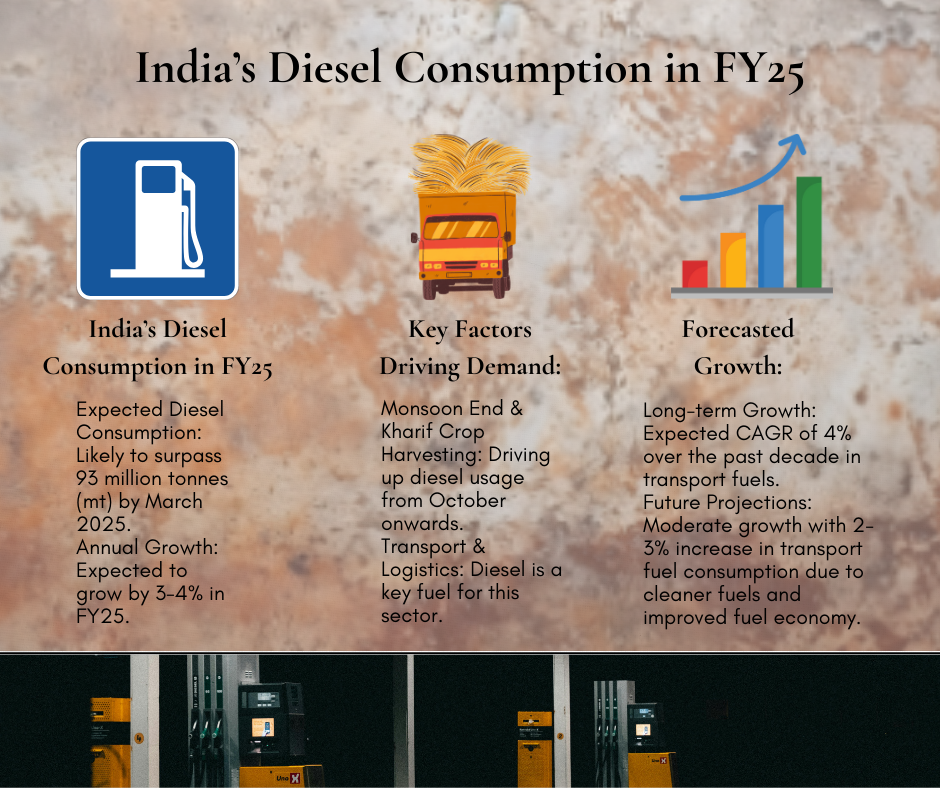

As India’s industrial sector continues to expand, the demand for high-quality diesel fuel has grown. Diesel-powered equipment is integral to sectors such as manufacturing, transportation, and power generation, making regular fuel testing essential for maintaining smooth operations. Diesel testing labs not only help businesses ensure the quality and performance of their fuel but also support compliance with environmental standards. With increasing pressure to reduce emissions and minimize environmental impact, proper diesel testing plays a critical role in India’s path toward sustainability.

Conclusion

The need for diesel testing in India cannot be overstated. Diesel is a vital fuel for various industries, and ensuring its quality is paramount to maintaining operational efficiency, reducing costs, and meeting environmental regulations. Testing LDO and HFO diesel fuels for factors such as sulfur content, calorific value, and contamination levels is essential to avoid equipment failure, reduce emissions, and optimize fuel use.

Diesel testing laboratories like Anacon Laboratories provide essential services that help businesses ensure the quality and compliance of their fuel, making them an indispensable part of India’s industrial ecosystem. With the increasing importance of sustainable and efficient fuel usage, the role of diesel testing labs will continue to grow, supporting the country’s industrial development while safeguarding the environment.

Leave a Reply